SMART RFID

INTRALOGISTICS

SMART RFID

INTRALOGISTICS

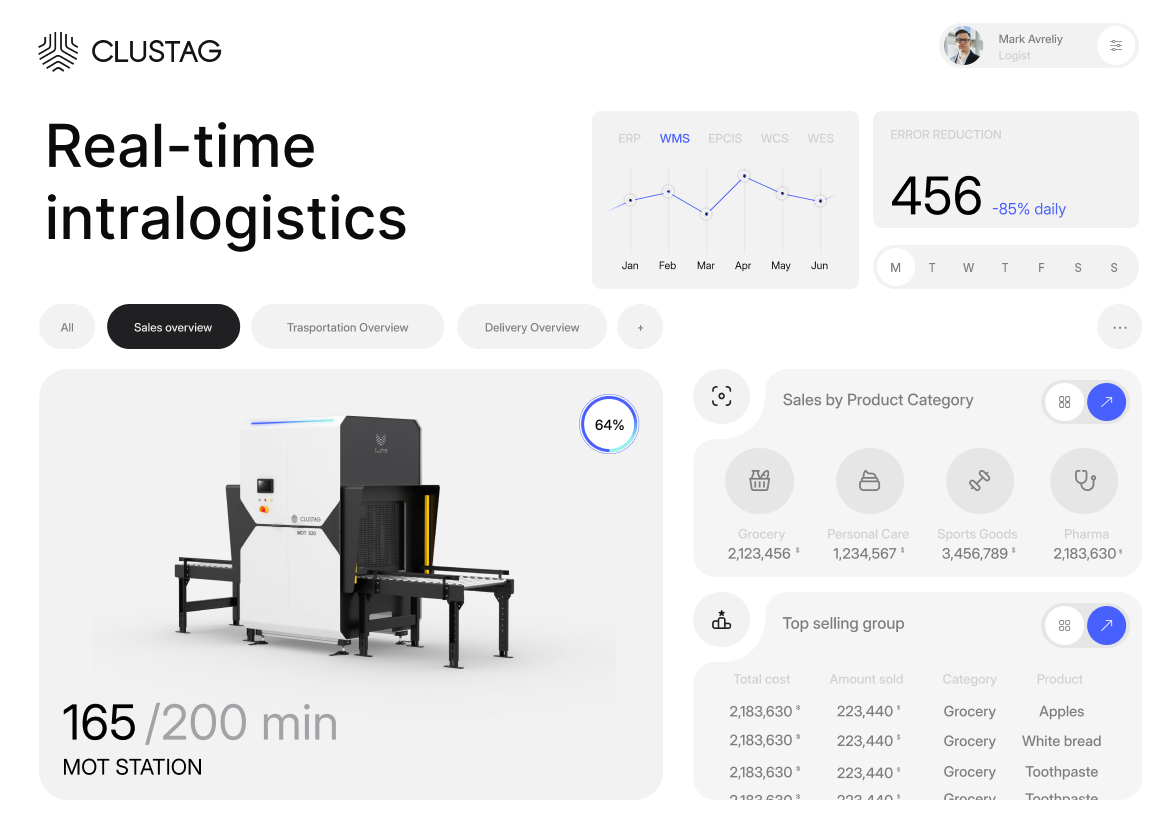

Clustag designs, manufactures, and installs RFID solutions to boost intralogistics operations worldwide.

Our ecosystem

We are committed to our customers’ success by offering them end-to-end RFID solutions. Our approach is based on adaptability, ensuring that we meet specific needs at every stage.

Our RFID solutions

We streamline your supply chain with Clustag’s advanced RFID solutions, tailored to ensure precision, efficiency, and complete traceability from inbound to outbound.

About us

At Clustag, we transform intralogistics through advanced RFID solutions that not only optimize processes but also create a positive impact on both people and businesses.

Revolutionizing RFID

Solutions Worldwide

Empowering industries worldwide with cutting-edge RFID technology for seamless integration, unmatched accuracy, and unprecedented speed.

Use case

RFID Solutions designed for seamless warehouse automation. Achieve 100% accuracy, reading up to 1,000 boxes.