SMART RFID

INTRALOGISTICS

SMART RFID

INTRALOGISTICS

Clustag designs, manufactures, and installs RFID solutions to boost intralogistics operations worldwide.

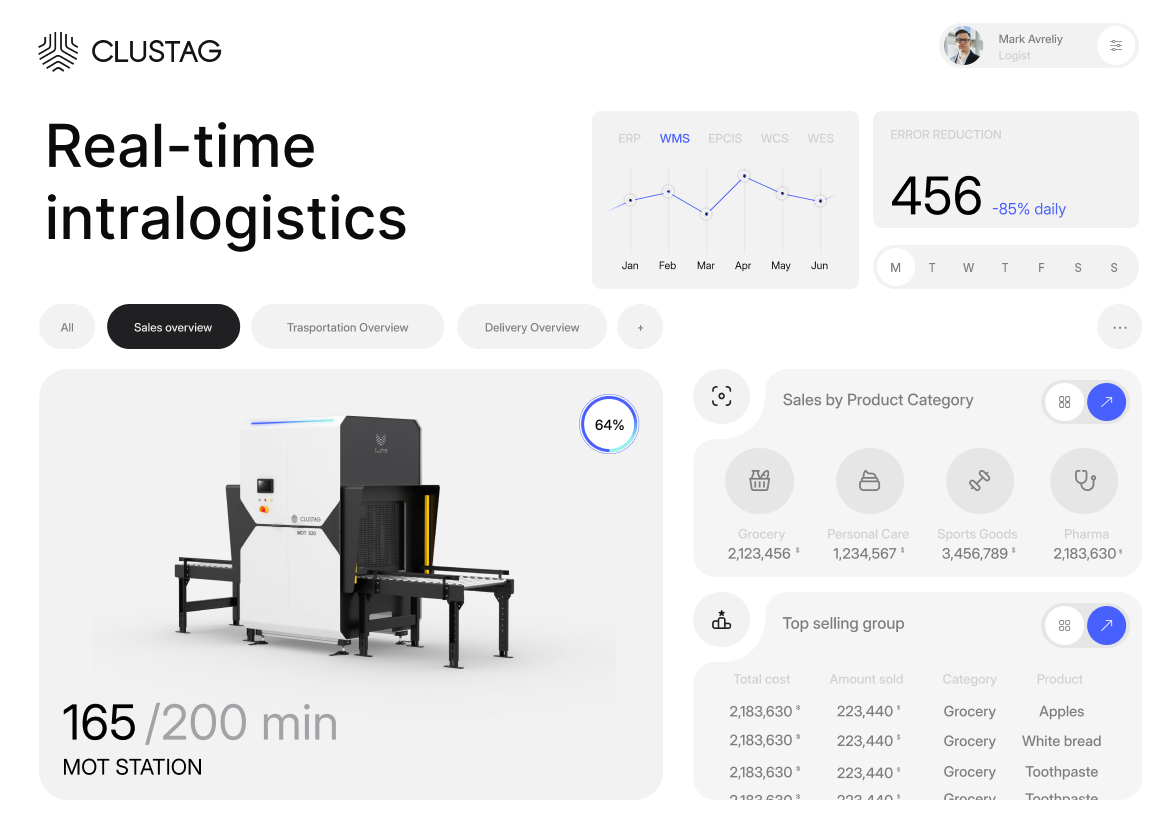

Smart Flow

We are committed to our customers’ success by offering them end-to-end RFID solutions. Our approach is based on adaptability, ensuring that we meet specific needs at every stage.

RFID Solutions

We streamline your supply chain with Clustag’s advanced RFID tunnels, tailored to ensure precision, efficiency, and complete traceability from inbound to outbound.

About us

At Clustag, we transform intralogistics through advanced RFID solutions that not only optimize processes but also create a positive impact on both people and businesses.

Unlocking the full potential of RFID

We believe in a future where technology is the key tool to empower

businesses and create a more connected, efficient, and sustainable world.

CLUSTAG

SMART FLOW

Powering RFID Intelligence Across Industries

- Retail & Apparel

- Sports Goods

- Personal Care & Beauty

- Pharma & Healthcare

- Grocery

- Postal & Courier Services