Hosted once every two years, MODEX brings together the entire supply chain ecosystem, showcasing the latest end-to-end solutions for the industry. Taking place in Atlanta, Georgia’s World Congress Centre from 11-14 March, expect to see the full spectrum of upcoming innovations in future-proofing manufacturing and supply chain operations.

This global event is designed to help professionals from around the world come together to learn about the latest sector trends through powerful keynote speaker sessions and over 150 free seminars from industry leaders.

If you’re a warehouse integration specialist looking to attend this year’s event, here’s what you can expect from MODEX 2024…

How RFID Technology Can Advance Supply Chains

Streamlined and efficient intralogistic operations can play an important role in helping businesses reduce overhead costs through optimised transportation and storage processes. It can help brands move items from manufacturer to customer faster and more effectively, enhancing revenue opportunities and benefiting a company’s bottom line while helping them remain agile to evolving demands.

Incorporating RFID empowers brands to enhance their warehouse operations. The technology enables users to automatically track all of their products at item-level as they move through the warehouse. This ultimately unlocks real-time tracking capabilities, high-quality inventory accuracy and increased efficiency, allowing for complete visibility across the supply chain.

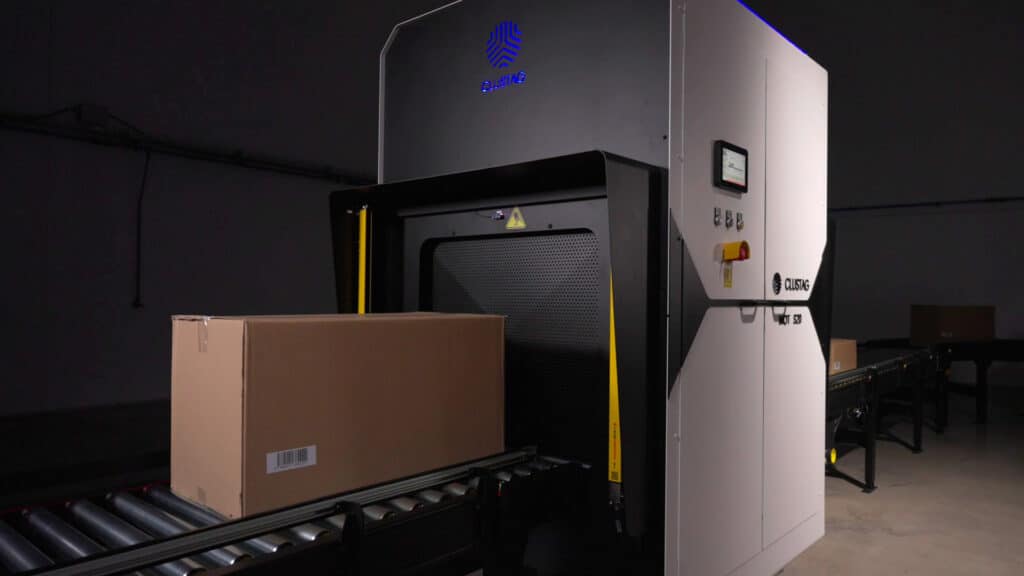

At MODEX, we will be providing an overview of our MOT Station. Delivering efficiency and reliability, the MOT station increases inventory accuracy by up to 99.92%, and is capable of scanning 400 tags per case at the speed of 1,000 cases per hour.

Incorporated with RFID shielding, the product ensures that only the contents within the MOT Station are scanned. Users can rest easy, safe in the knowledge that their inventory management practices are robust, reliable and efficient.

Developments Within Warehouse Automation

Typically, warehouse processes require significant labour efforts to control and oversee various actions. During times of labour shortages, this has the potential to cause issues for brands, which suffer from interrupted supply chains as a result of being understaffed throughout the supply chain. Furthermore, with manual inventory management practices in place, businesses become prone to human error, which can significantly reduce the accuracy of receiving and shipping within the warehouse.

Developments in warehouse technology are helping brands overcome both of these issues by enabling concepts such as warehouse automation. With repetitive tasks conducted automatically within supply chains, several processes no longer require on-hand support; including inventory management.

With solutions in place, such as Clustag’s MOT Station, which automates the receiving process within warehouses, the risk of human error is significantly reduced, enhancing inventory management practices while enabling warehouse staff to better spend their time on other valuable tasks.

Automation is expected to be a key trend across MODEX 2024, and for the first time we will be providing live demonstrations of our MOT Station, which is designed to deliver automation to warehouse operations while providing real-time, accurate visibility of stock.

Streamlining Materials Handling Within Distribution Centres

At this year’s MODEX event, some materials-handling businesses will be focused on finding the right solution to help them deliver efficiency within the distribution centre. Day 3 of the trade show will provide visitors with an in-depth view of exactly how this can be achieved through RFID.

Manolo Reguart, Director of Business Development, Strategy and Alliances at Rielec, will host Dean Frew, President of RFID Solutions at SML Group, in Theater B at 3 pm to discuss how the technology can enable the material handling systems to improve inventory accuracy and supply chain compliance in distribution centres.

RFID and automation each play a significant role in improving inventory accuracy and enhancing supply chain compliance within distribution centres. The right deployment allows staff to gain visibility over the type, quantity and location of products within the distribution centre, and enables tracking throughout the supply chain, minimising human error.

Our RFID solutions specifically target challenges with packaging, operations, and storage. This helps logistics companies gain complete visibility over the whereabouts and numbers of the stock they are processing.

We’ll Be There!

Stop by booth B10005, to learn more about how Clustag’s MOT Station can transform a business’s supply chain solutions, delivering efficiency, reliability and accuracy to inventory management.

To find out more about how Clustag can help warehouse integration specialists deliver supply chain automation to their clients, talk to us today.

*Results obtained from mass testing for products labelled according to Auburn University’s international standards, and for items composed of non-conflicting materials for RFID environments.